Segmental Launching Gantry

Segmental Launching Gantry is generally used in the erection of Highway Bridge and MRT Bridge, using precast segmental prestressed concrete box beam (PC beam) assembly. HL-Kattor segmental launching gantries have great efficiency in self-traveling construction is the key characteristic. The main beam, leg, and winch trolley make up its construction. The main girder serves as the load-bearing component, while the legs serve as the transverse and longitudinal movement, leveling, support, cross span, cross-scale, and other components. The precast girder is raised using a winch trolley.

Parameter

JP75 Segmental launching gantry

Technical Parameters

Span | 50m/75m (Min/Max) |

Grade of the machine | A3 |

Maximum Longitudinal slope | ±2.35%,_3.4% |

Bridge Transverse Slope | ±2% |

Min.curve radius | 2500m |

Max. Lifting weight | 150ton |

Spreader rotation | 360° |

Girder feeding method | Below |

Overall size | L120×W11.8m×H14mW |

Weight and power | 680t, 210kw |

Project where JP75 Segmental launching gantry was employed

Babahoyo River Bridge in Guayaquil City, Equador.

JP 1500-75 Segmental Launching Gantry

Technical parameters

Span | 60m (also for 50m, 75m) |

Min. Curve radius | ≥1500m (60m span) |

Max. Handling weight | Semi-span 1500t/ 10pcs (75m) Semi-span 1000t/ 9pcs (75m) Semi-span 1500t/ 13pcs (75m) |

Max. Segment weight | 160t |

Longitudinal moving speed | 2m/min |

Lifting weight/ height | 180t (including hook, 60m) |

Lifting/ moving speed of hoisting trolley | 0-3m/min; 0-15m/min |

Project name

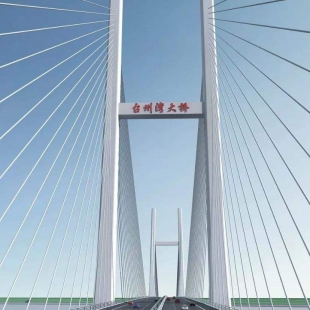

Taizhou Bay Bridge project

JP2000-75 Segmental launching Gantry

Technical parameters

Capacity | 2000ton |

Span | 39m-75m |

Segment weight | 220t |

Spreader Rotating angle | 360° |

Total length | 188m |

Self-weight | 1800t |

Lifting height | 70m |

Moving speed | 0-1m/min |

Horizontal moving speed | 0.5m/min |

Girder feeding method | Front/ Rear/ Below |

Segmental assembling methods | Full-span cantilever assembling Symmetrical cantilever assembling Semi-span cantilever assembling |

Project description

This segmental launching gantry is by far the largest in China. The design is versatile, takes into account various operating situations, and automatically adjusts the supporting leg and rotating spreader. The equipment can be used to build segmental bridges with a span under 75 meters.

LG40 Segmental Launching Gantry

Project name

Central-Wanchai- Bypass Project in Hongkong

Technical parameters

Span | 40m, 30m, 28m |

Grade of machine | A3 |

Maximum Longitudinal slope | 2.50% |

Bridge transverse slope | ±2.5%, ±3.7% |

Minimum curve radius | ≥ 300m |

Maximum lifting weight (without hook) | 160t |

Spreader rotation | 360° |

Adjusting angle of spreader | ±5% |

Girder feeding method | Rear feeding and below feeding |

Project description

The CWB is 4 kilometers long. It is constructed on the Central and Wanchai reclamation area, and it features interchange points that connect Central, Wanchai, and Causeway Bay.

Equipment description

The LG40 segment bridge launching gantry is 104 meters in length, is 4.35 meters tall, and weighs 335 tons. The main beam, front, middle, and back supporting legs, main hoisting trolley, 12.5-ton moving trolley, spreader, hanger, tensioning platform, hydraulic system, electric system, anchoring system, and numerous other components make up the entire machine.

Related Cases